There are many names used for mineral casting materials internationally, the most common of which are the following:

-Polymer casting:Polymer casting

- Mineral casting: Mineral casting

- Resin-cement concrete:resin-cement concrete

-Polymer concrete:polymer concrete

- nonmetal synthetic materials: nonmetal synthetic materials

- Artificial granite for machinery: Machinery polymer composite

Next, we will introduce mechanical artificial granite in detail in a question and answer format.

1. Q: What is artificial granite for machinery (Machinery polymer composite)?

A: It is a highly filled composite material made of natural granite particles as the main aggregate and organic resin as the binder.

2. Q: What is composite?

A: Combine two or more substances of different phases and capture the advantages of each component to form the required structure.

3. Q: What are the main uses of artificial granite for machinery?

A: This material is a new type of material popular in the international machinery industry. It can replace traditional cast iron and be used in key parts such as machine tool beds, bases, beams, columns, etc. to improve the stability of the machine tool and thereby improve the accuracy of the machine tool.

- Mechanical field: milling machines, machining centers, cylindrical grinders, surface grinders, tool grinders, lathes, EDM equipment, boring grinders and grinding machines, laser cutting machines, automatic punching machines and punching machines, etc.

- Measurement fields: three-dimensional coordinate measuring machines, measuring blocks, balancing machines, test benches, various experimental devices, etc.

- Semiconductor field: connectors, automatic insertion machines, analysis equipment and inspection equipment, wafer (sheet) processing and testing, printed circuit board drilling machines, etc.

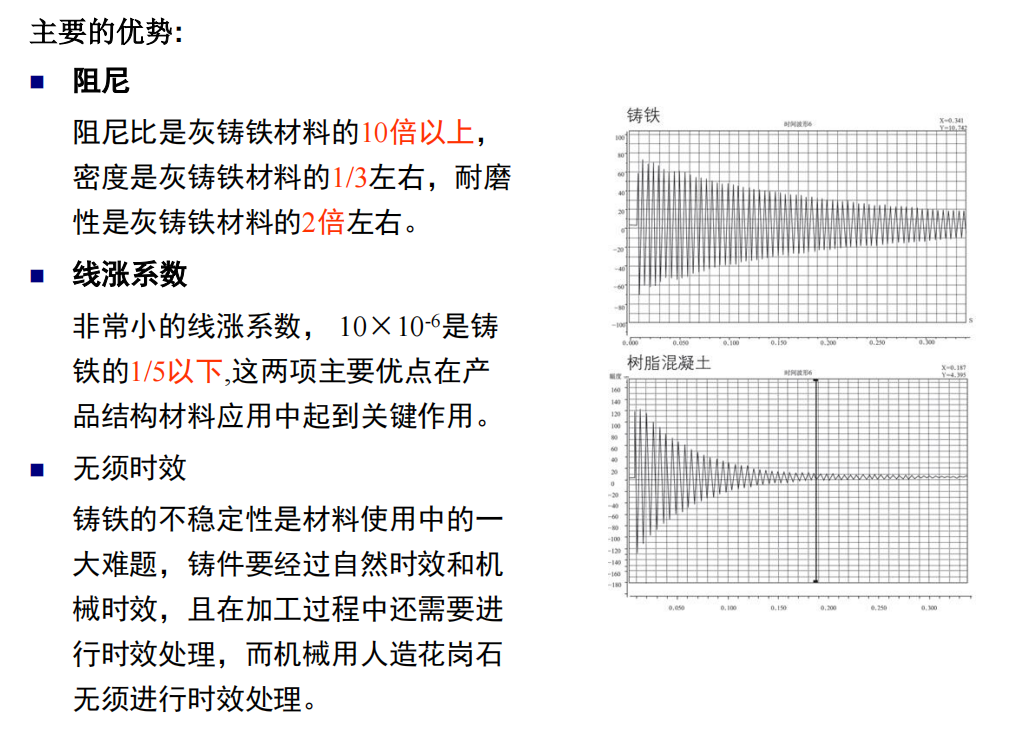

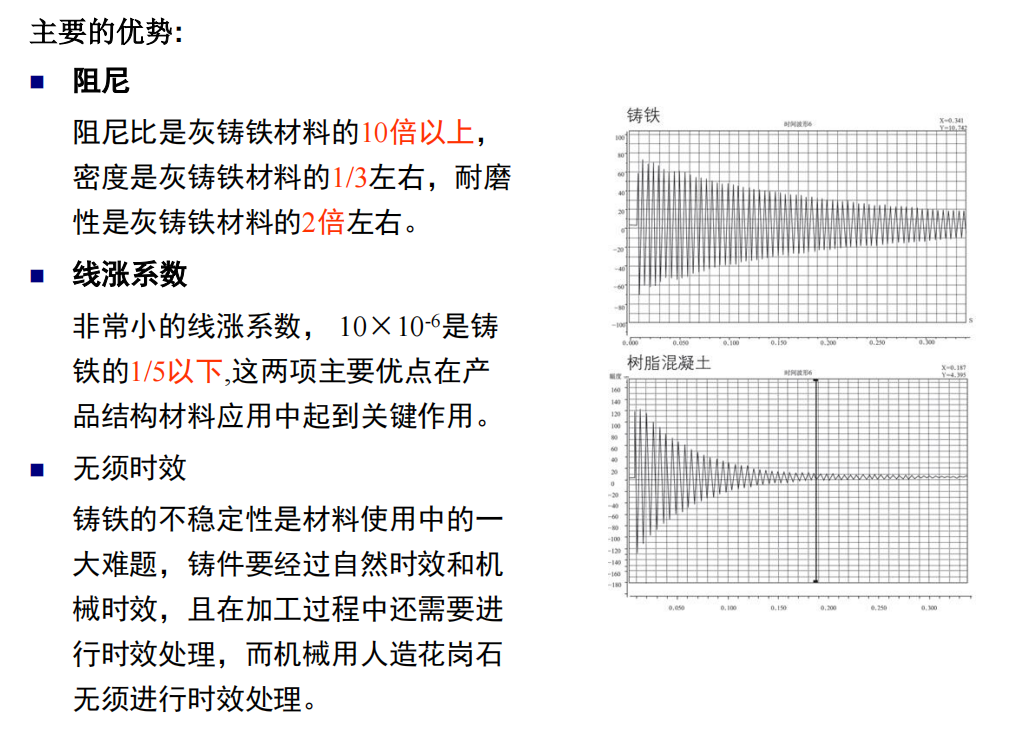

4. Q: What are the advantages and disadvantages compared with gray cast iron?

A: Advantages: damping and shock absorption, high precision, cost reduction, heat resistance, corrosion resistance, flexible design, green and environmentally friendly.

Disadvantages: The compressive and tensile strength are lower than gray cast iron, so the mechanical properties of the material directly determine the quality of mineral casting materials.

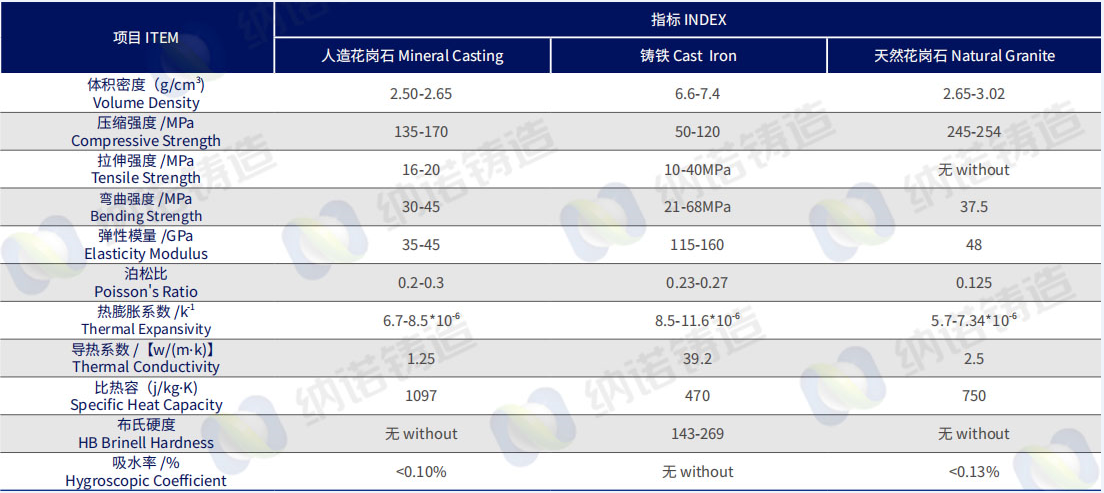

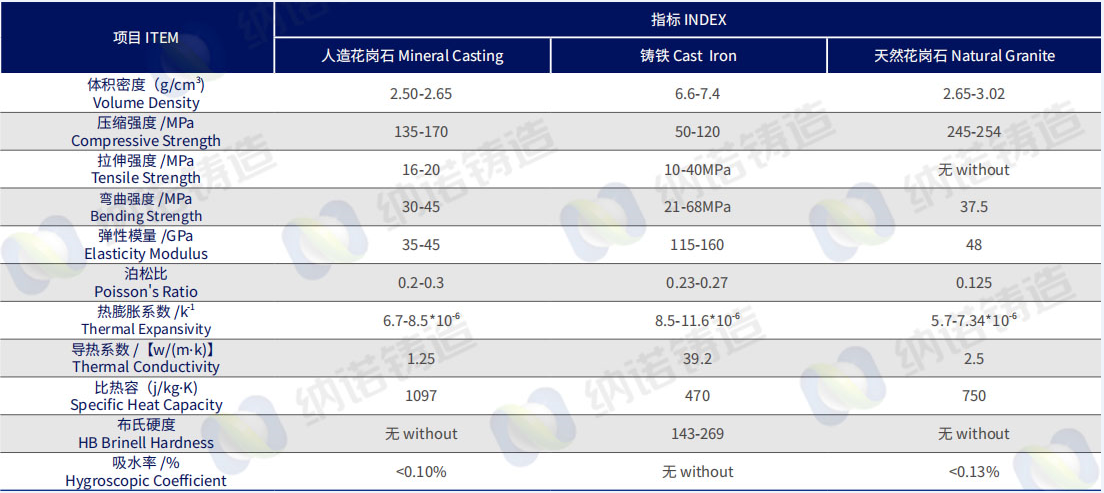

5. Q: Compared with gray cast iron, what are the mechanical properties of Nano brand artificial granite for machinery?

A: See the picture below

6. Q: How does Nano achieve the optimal mechanical properties of artificial granite for mechanical use?

A: Since the mechanical properties of mineral castings are subject to the preparation process and the proportion and selection of components, it is very important whether the process is scientific and reasonable, and whether the selection of materials meets the composite material gradation requirements.

7. Q: What are the ways to reduce costs in the promotion and application of artificial granite for machinery?

A: The best way to reduce costs is concurrent engineering, that is, when performing structural design, the components related to the machine tool are pre-embedded using the cold pouring characteristics of mineral castings, and no secondary assembly is required.It can save the cost of secondary finishing and machining, and reduce the use of expensive structural materials as much as possible; integrate complex parts, and the diversified structure reduces the number of system parts and assembly time.This feature of no need for aging can also speed up capital turnover and improve capital utilization, so that the overall cost will be lower than using gray cast iron.

8. Q: Why choose Nano when using mineral castings?

A: Dongxing Precision Measuring Instrument, the predecessor of Nano, has been engaged in the processing of natural granite measuring instruments since 1989. It has natural advantages in the characteristics of granite, measuring tools and measurement methods.In addition, Nano is a professional mineral casting manufacturer with complete intellectual property rights. It has a national patent for artificial granite for machinery and is the national standard setter for mineral castings.Scientific and superior material formulas, advanced molding equipment and process control imported from Germany ensure the mechanical properties of mineral castings.Many international high-end machine tool industries are using Nano mineral castings. More than 30 years of industry experience ensure that Nano is your most reliable choice!